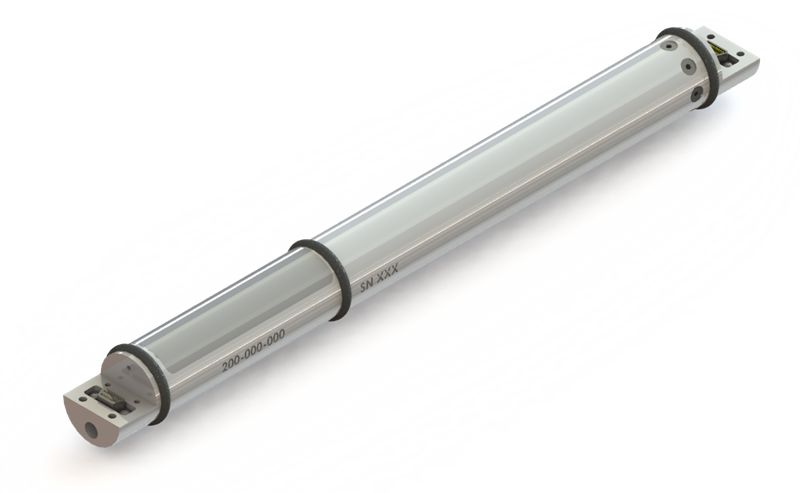

NGT-T Gamma Tool

NGT-T

Non-Directional Gamma Tool (1.36” OD)

Non-Directional Gamma Tool (1.36” OD)

The NGT-T (Natural Gamma Tool-Tensor) is the largest selling MWD gamma tool on the market! Initially developed for Tensor in 1993, the NGT-T helped propel the momentum of horizontal and directional drilling worldwide. It has been the workhorse of the independent drilling industry for over 30 years. With more than 6,000 units currently being used in the field worldwide, there is no other gamma tool that even comes close. The NGT-T has been continuously and incrementally enhanced and improved as the MWD/DD downhole tools industry matured over the years.

A newer version of the NGT-T is now available as the NGT-T2, and is a large leap forward in legacy gamma design.

Electronics and Dual-Board Design

The NGT-T contains CBG’s dual-board design. Both boards are encapsulated and cushioned within pre-molded pads that provide superior shock and vibration protection, eliminating potential thermal expansion of flowed potting materials around and under electronic components.

The thru-wires in the NGT-T are externally routed.

Compatibility and Upgradeability

The NGT-T is designed for compatibility with Tensor style MWD system specifications, and contains 15-pin high temperature Micro-D Subminiature (MDM) connectors on the top (male pin) and bottom (female socket). All 15 wires pass through the tool from top to bottom connectors. The gamma tool utilizes three wire connections, Pin1 (GND), Pin4 (DC Power) and Pin8 (Signal Out).

Unlike the NGT-T2, the NGT-T not upgradable to the higher 190°C temp NGT-HTR Gamma Tool.

To protect your gamma investment and ensure the best performance use CBG original SNB Snubbers-Shock & Vibration Isolators.

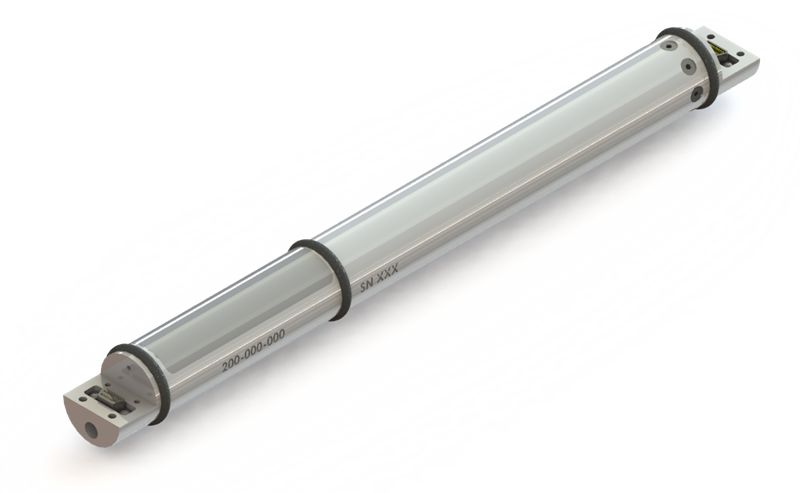

NGT-T

Non-Directional Gamma Tool (1.36” OD)

The NGT-T (Natural Gamma Tool-Tensor) is the largest selling MWD gamma tool on the market! Initially developed for Tensor in 1993, the NGT-T helped propel the momentum of horizontal and directional drilling worldwide. It has been the workhorse of the independent drilling industry for over 30 years. With more than 6,000 units currently being used in the field worldwide, there is no other gamma tool that even comes close. The NGT-T has been continuously and incrementally enhanced and improved as the MWD/DD downhole tools industry matured over the years.

A newer version of the NGT-T is now available as the NGT-T2, and is a large leap forward in legacy gamma design.

Electronics and Dual-Board Design

The NGT-T contains CBG’s dual-board design. Both boards are encapsulated and cushioned within pre-molded pads that provide superior shock and vibration protection, eliminating potential thermal expansion of flowed potting materials around and under electronic components.

The thru-wires in the NGT-T are externally routed.

Compatibility and Upgradeability

The NGT-T is designed for compatibility with Tensor style MWD system specifications, and contains 15-pin high temperature Micro-D Subminiature (MDM) connectors on the top (male pin) and bottom (female socket). All 15 wires pass through the tool from top to bottom connectors. The gamma tool utilizes three wire connections, Pin1 (GND), Pin4 (DC Power) and Pin8 (Signal Out).

Unlike the NGT-T2, the NGT-T not upgradable to the higher 190°C temp NGT-HTR Gamma Tool.

To protect your gamma investment and ensure the best performance use CBG original SNB Snubbers-Shock & Vibration Isolators.

NGT-T Specifications

P/N 200-000-000

| Detector | Scintillator Crystal | Sodium Iodide, Na(TI) |

|---|---|---|

| Photomultiplier | R3991A (Hamamatsu) | |

| Mechanical | Diameter (OD) | 1.36” |

| Length (make-up) | 13.6” | |

| Weight | 1.7 lb. | |

| End Connectors | Micro-D Subminiature, 15-Pin | |

| Material | Aluminum Alloy | |

| Performance | Sensitivity | 1.14 CPS/API* |

| Accuracy | +/- 5% to 150°C +/- 10% to 175°C |

|

| Environmental | Operating Temperature | -18°C to 175°C** |

| Survival Temperature (reduced accuracy) | -40°C to 200°C | |

| Heat/Cool Rate, Max. | 2.8°C (5°F) per minute | |

| Vibration (3 axis) 50-1000Hz, Random | 30G (20G RMS)** | |

| Shock (3 axis) | 1000G, 0.5ms, half-sine | |

| Power Requirements | DC Input Voltage | 17-48 VDC, 50VDC Max.** |

| Tool Current | 8-11 mA | |

| Output Signal | Negative Pulse | +5V to GND, 5 uSec width |

* Counts are collected with gamma tool mounted within a standard BeCu pressure barrel, (OD 1.875″, ID 1.500″). API Calibration performed with AEA Technology, QSA Inc., KUTh Field Verifier #188074, S/N 255 Radionuclides: K-40(11.7%), U-238(90 ppm), Th-232(40 ppm).

** Compare to NGT-T2