DDG Dual Detector Gamma Tool

DDG

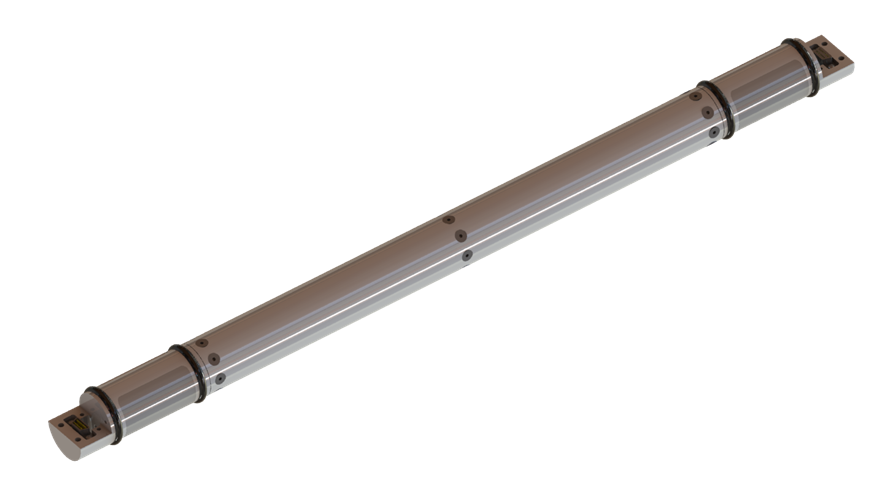

Dual-Directional Gamma Tool (1.40” OD)

The new CBG Dual Detector MWD Gamma tool for Azimuthal Geosteering consists of two opposed, tungsten-collimated shielded Nal(TI) scintillation detectors housed within a single ruggedized assembly. Each detector contains its own set of electronics for powering its photomultiplier tube and processing the detected gamma signals.

The new CBG Dual Detector MWD Gamma tool for Azimuthal Geosteering consists of two opposed, tungsten-collimated shielded Nal(TI) scintillation detectors housed within a single ruggedized assembly. Each detector contains its own set of electronics for powering its photomultiplier tube and processing the detected gamma signals.

Two 72° “windows” are machined along the length of the Tungsten shield positioned 180° apart from one another. The eccentric tungsten shielding has a 0.23” maximum thickness that provides the highest front to back gamma count ratio. It is designed to maximize gamma rays entering the crystal through the window while effectively blocking them from penetrating the non-window area of the crystal. This unique shielding design and dual detectors effectively doubles the tool sensitivity while maintaining directionality.

The DDG supplies an output signal from each detector for processing in a customer supplied controller. Power and GND are input to either MDM connector. Output counts from each detector can be individually processed or summed together. In addition, either tool can be turned off if a problem is detected by the controller.

To protect your gamma investment and ensure the best performance use CBG original SNB Snubbers-Shock & Vibration Isolators.

DDG

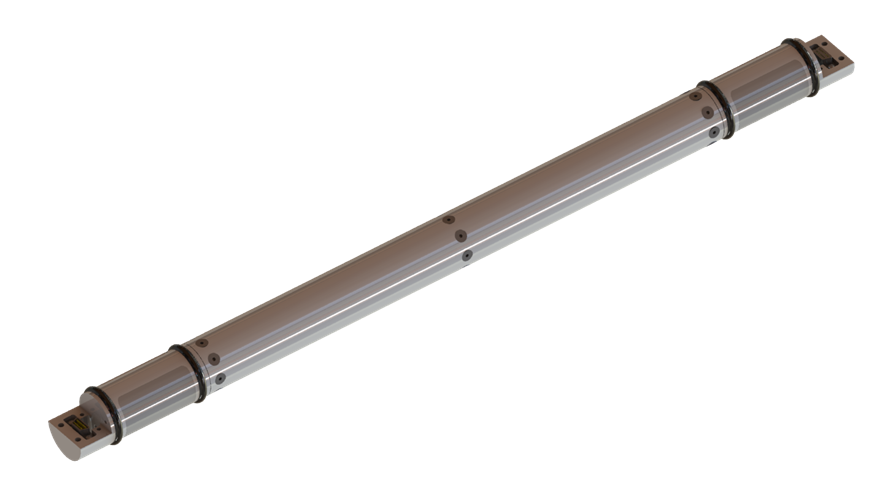

Dual-Directional Gamma Tool (1.40” OD)

The new CBG Dual Detector MWD Gamma tool for Azimuthal Geosteering consists of two opposed, tungsten-collimated shielded Nal(TI) scintillation detectors housed within a single ruggedized assembly. Each detector contains its own set of electronics for powering its photomultiplier tube and processing the detected gamma signals.

Two 72° “windows” are machined along the length of the Tungsten shield positioned 180° apart from one another. The eccentric tungsten shielding has a 0.23” maximum thickness that provides the highest front to back gamma count ratio. It is designed to maximize gamma rays entering the crystal through the window while effectively blocking them from penetrating the non-window area of the crystal. This unique shielding design and dual detectors effectively doubles the tool sensitivity while maintaining directionality.

The DDG supplies an output signal from each detector for processing in a customer-supplied controller. Power and GND are input to either MDM connector. Output counts from each detector can be individually processed or summed together. In addition, either tool can be turned off if a problem is detected by the controller.

To protect your gamma investment and ensure the best performance use CBG original SNB Snubbers-Shock & Vibration Isolators.

DDG Specifications

P/N 206-000-000

| Detector | Scintillator Crystal (X2) | Sodium Iodide, Na(TI) |

|---|---|---|

| Photomultiplier (X2) | R3991A (Hamamatsu) | |

| Mechanical | Diameter (OD) | 1.40” |

| Length (make-up) | 22.17” | |

| Weight | 5.5 lb | |

| End Connectors | Micro-D Subminiature, 15-Pin | |

| Material | Aluminum Alloy (chassis), Tungsten (shield) | |

| Performance | Sensitivity | 0.29* CPS/API (each detector) |

| Front/Back Count Ratio (using source at 6”) | 14.0 using Barium-133 2.72 using Cesium-137 |

|

| Accuracy | +/- 5% to 150°C +/- 10% to 175°C |

|

| Environmental | Operating Temperature | -18°C to 175°C |

| Survival Temperature (reduced accuracy) | -40°C to 200°C | |

| Heat/Cool Rate, Max. | 2.8°C (5°F) per minute | |

| Vibration (3 axis) 50-1000Hz, Random | 30G (20G RMS) | |

| Shock (3 axis) | 1000G, 0.5ms, half-sine | |

| Power Requirements | DC Input Voltage | 17-48 VDC, 50VDC Max. |

| Tool Current | 18 mA – 22mA | |

| Output Signal | Negative Pulse | +5V to GND, 5 uSec width |

* Counts are collected with gamma tool mounted within a standard BeCu pressure barrel, (OD 1.875″, ID 1.500″). API Calibration performed with AEA Technology, QSA Inc., KUTh Field Verifier #188074, S/N 255 Radionuclides: K-40(11.7%), U-238(90 ppm), Th-232(40 ppm)