MWD/LWD Gamma for Oil & Gas Drilling

Gamma Ray tools produce a measurement of the naturally occurring gamma radiation found in rock formations. The Gamma Log produced by these Gamma Ray Sensors is most commonly used for Geosteering, correlation with existing open hole logs, identifying low and high radiation lithologies and depth correlation. In current unconventional horizontal drilling, the Gamma Log is critical in the identification of high gamma emitting shales. CBG produces the largest variety of Measurement while Drilling (MWD) gamma tools for radiation monitoring and detection in the market.

Gamma Ray tools produce a measurement of the naturally occurring gamma radiation found in rock formations. The Gamma Log produced by these Gamma Ray Sensors is most commonly used for Geosteering, correlation with existing open hole logs, identifying low and high radiation lithologies and depth correlation. In current unconventional horizontal drilling, the Gamma Log is critical in the identification of high gamma emitting shales. CBG produces the largest variety of Measurement while Drilling (MWD) gamma tools for radiation monitoring and detection in the market.

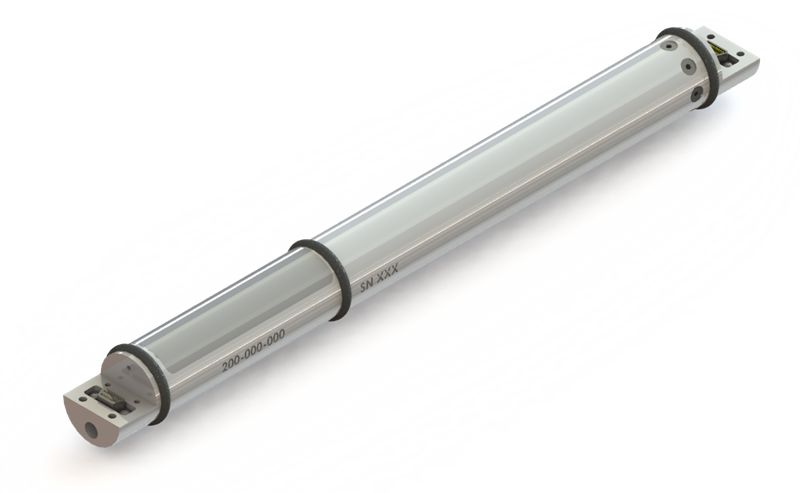

CBG offers three different diameters of tools for both Probe based and Collar-Mounted systems. With overall diameters of 1.36”, 1.05” and 0.75”, we have a gamma tool for any of your applications. In addition to gross counting systems where gamma rays are detected from all directions around the tool we also have “focused” sensors that will measure detect gamma rays from specific directions only.

We understand that our customers may have specific design requirements that are not completely met by our existing product line. Should this be the case, our engineering group is ready to create a cost effective custom proprietary design. Over the years, we have produced more than a dozen custom tools for customers around the world.

All CBG gamma tools consist of a custom, super sensitive hermetically sealed Sodium Iodide Scintillator crystal, Nal(TI), coupled to a ruggedized high temperature Photomultiplier for maximum log quality. Mechanical design techniques have been developed and continually improved specifically for the MWD Directional Drilling environment to ensure reliable performance. Short single piece aluminum chassis not only provides maximum strength and rigidity but minimizes vibration loads due to the low mass.

Gamma tool electronics are fully temperature compensated to maintain consistent output count rates through 175°C (350°F) and up to 190°C (374°F) on select models. The tools will survive temperatures as high as 200°C (392°F). Every CBG gamma tool, whether new or repaired, is adjusted and logged in ovens from room temperature to 175°C and back to room temperature, to ensure a count rate stability of no less than 90%, however typical drift is no more than 5%. The new Highly Accelerated Stress Screening (HASS) system allows tools to be vibrated throughout the temperature test to accurately simulate actual downhole conditions.

A gross counting discriminator with an energy threshold set at approximately 15KeV, significantly lower than other tools, results in higher count rates and greater accuracy.

Electronics are fully encapsulated for additional shock and vibration protection. The scintillator crystal and photomultiplier are packaged in-house, utilizing our proprietary and unique design, for ease of service and repair while retaining full shock ratings.

All CBG gamma ray detector tool electronics include the “power-down” option as defined in the qBus standard that allows powering off the tool in order to save batteries. This is accomplished by the Controller pulling the gamma output line to ground potential. When this occurs, all internal electronics functions are disabled with a small trickle current of less than 1mA remaining.

CBG gamma tools incorporate a floating battery ground connection enabling the use of EM telemetry systems.

Gamma Ray tools produce a measurement of the naturally occurring gamma radiation found in rock formations. The Gamma Log produced by these Gamma Ray Sensors is most commonly used for Geosteering, correlation with existing open hole logs, identifying low and high radiation lithologies and depth correlation. In current unconventional horizontal drilling, the Gamma Log is critical in the identification of high gamma emitting shales. CBG produces the largest variety of Measurement while Drilling (MWD) gamma tools for radiation monitoring and detection in the market.

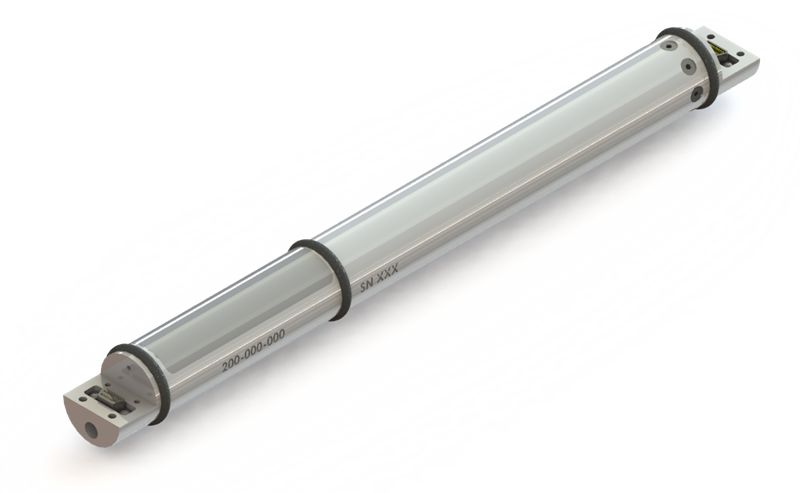

CBG offers three different diameters of tools for both Probe based and Collar-Mounted systems. With overall diameters of 1.36”, 1.05” and 0.75”, we have a gamma tool for any of your applications. In addition to gross counting systems where gamma rays are detected from all directions around the tool we also have “focused” sensors that will measure detect gamma rays from specific directions only.

We understand that our customers may have specific design requirements that are not completely met by our existing product line. Should this be the case, our engineering group is ready to create a cost effective custom proprietary design. Over the years, we have produced more than a dozen custom tools for customers around the world.

All CBG gamma tools consist of a custom, super sensitive hermetically sealed Sodium Iodide Scintillator crystal, Nal(TI), coupled to a ruggedized high temperature Photomultiplier for maximum log quality. Mechanical design techniques have been developed and continually improved specifically for the MWD Directional Drilling environment to ensure reliable performance. Short single piece aluminum chassis not only provides maximum strength and rigidity but minimizes vibration loads due to the low mass.

Gamma tool electronics are fully temperature compensated to maintain consistent output count rates through 175°C (350°F) and up to 190°C (374°F) on select models. The tools will survive temperatures as high as 200°C (392°F). Every CBG gamma tool, whether new or repaired, is adjusted and logged in ovens from room temperature to 175°C and back to room temperature, to ensure a count rate stability of no less than 90%, however typical drift is no more than 5%. The new Highly Accelerated Stress Screening (HASS) system allows tools to be vibrated throughout the temperature test to accurately simulate actual downhole conditions.

A gross counting discriminator with an energy threshold set at approximately 15KeV, significantly lower than other tools, results in higher count rates and greater accuracy.

Electronics are fully encapsulated for additional shock and vibration protection. The scintillator crystal and photomultiplier are packaged in-house, utilizing our proprietary and unique design, for ease of service and repair while retaining full shock ratings.

All CBG gamma ray detector tool electronics include the “power-down” option as defined in the qBus standard that allows powering off the tool in order to save batteries. This is accomplished by the Controller pulling the gamma output line to ground potential. When this occurs, all internal electronics functions are disabled with a small trickle current of less than 1mA remaining.

CBG gamma tools incorporate a floating battery ground connection enabling the use of EM telemetry systems.